Your task

It is crucial to simulate, measure and test the rechargeable batteries used in battery-powered devices and vehicles. Overcharging and deep discharging reduce the lifetime of rechargeable batteries. Defects could lead to overheating of a battery and even cause a fire. Larger batteries are typically built by connecting multiple cells in series and parallel. Since the same charge and discharge current flows through all cells, individual differences in battery capacity, self-discharging, etc. would lead to differing states of charge (SoC) over time and consequently limit the capacity and lifetime of the battery.

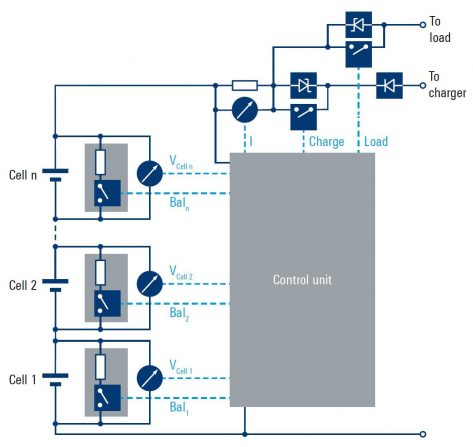

Battery management systems (BMS) actively monitor, control and manage various battery cell parameters.

The tasks of a BMS are:

- Determining the SoC of each cell

- Supervising the integrity and derating of each cell

(state of health, SoH) - Detecting faults and exceptional conditions and preventing hazards such as overheating and fire

- Balancing the SoC between the cells

- Thermal and energy management

Balancing can be implemented in a passive way by selectively loading the cells having the highest charge during the charging process or by using switch-mode regulators to actively transfer energy from the cells with the highest state of charge to those with the lowest state of charge. Since BMSs play a crucial role in battery life and fail safety, they have to be tested thoroughly. The tests have to simulate all conditions that could possibly occur in operation.

Rohde & Schwarz solution

The NGL200 and NGM200 DC power supplies from Rohde & Schwarz are versatile devices with all the functions required for testing and validating battery management systems.

The NGL200 and NGM200 support two-quadrant operation as source and sink. Source currents up to 6 A and sink currents up to 3 A are possible. All outputs are fully isolated against ground. They can be connected in series to emulate battery packs on a single cell level up to a maximum voltage of 250 V against ground. The adjustable output impedance can be set between –50mΩ and 100Ω. Current and voltage measurements at the power supply output deliver high-resolution values.

All functions can be fully remote controlled with command processing times of less than 6 ms.

In addition, the NGM200 power supply series features an optional battery simulation mode that allows realistic simulation of different predefined or user-defined cell types. Opencircuit voltage and internal resistance depending on the state of charge are defined for each cell type in an ASCII file. These features allow the cell properties to be simulated and varied over time with high precision and high time resolution. For small and medium-sized batteries, the cell current can be drawn directly out of the power supplies.

For larger batteries like those used in automotive applications, it is not necessary for the charging and discharging currents to physically flow for the BMS tests. Current measurement results, e.g. voltages across shunt resistors, are simulated to the BMS, and the power supplies establish the cell voltages and deliver the balancing currents.

Battery simulation

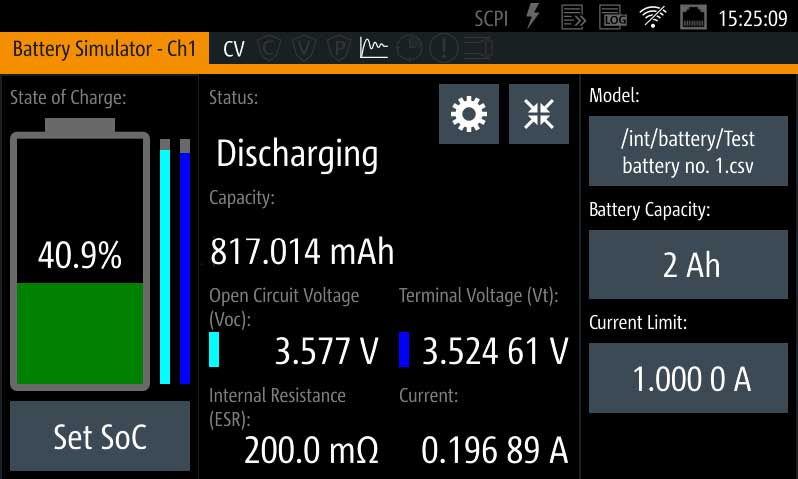

Battery simulation: the main parameters to characterize a battery’s condition are summarized in one display.

The battery simulation software includes data sets of common battery types that can be easily modified.

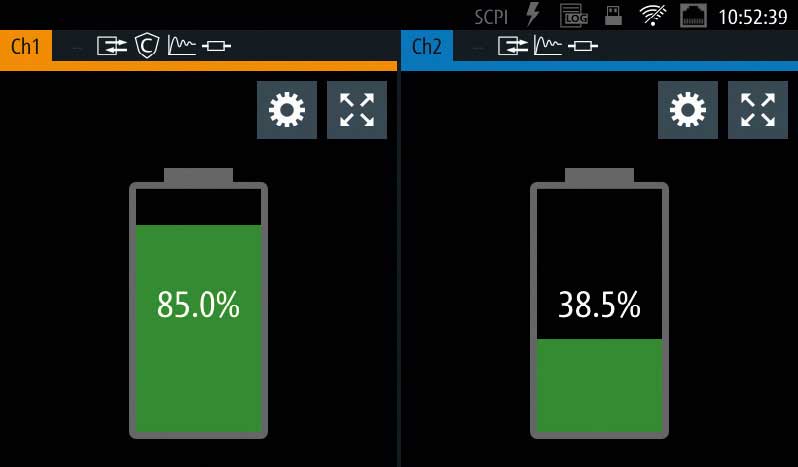

Using the two-channel R&S®NGM202, battery simulation can be used simultaneously on both channels.

Battery simulation with NGM200

In particular, when battery-operated devices have to be optimized for lifecycle, the discharging behavior of the bat-tery type needs to be considered. The battery simulator function of the NGM200 makes it possible to simu-late the real battery output performance. Testing can be based on a selected battery model, and battery capacity, SoC and Voc can be set to any state to test the device un-der specific circumstances. The charging behavior of a battery can also be simulated. This is particularly important when designing battery chargers. In this application, the NGM200 power supply is used in sink mode.Both cases provide dynamic simulation, meaning Voc, ESR and SoC change according to charging/discharging conditions like a real battery. The state of charge is shown graphically; all other values are displayed numerically.

Battery models

Real batteries show different characteristics depending on the type of battery and its charging condition. Capacity, open circuit voltage (Voc) and equivalent series resistance (ESR) are important battery characteristics that depend on its state of charge (SoC). The optional NGM-K106 functionality allows users to simulate the behavior of batteries under different charging conditions, e.g. when powering a DUT.

To define a battery model, the data of the battery can be entered easily using the integrated battery model editor. Data sets for the common battery types Pb, LiIon, NiCd and NiMH are available as preconfigured files. These can be easily modified according to the needs of a specific application. Additional battery model data sets can be loaded from a USB device and stored on the NGM200 power supplies.

Battery Modelling Tool for the NGM and NGU to build a battery model from the discharge log file of your battery This python script outputs one .csv file for your NGM/NGU. (Python 3.7 environment is required for this). (ext. Link zu R&S -Python-script)

Summary

The compact form factor of the NGM and NGL power supplies and their max 2 channels per unit allow flexible configuration and space-saving setups for testing a BMS. A 19″ rackmount kit and backplane connections provide easy and rugged integration into racks.

Beyond the NGM-K106 battery simulation option, the NGM200 power supply series provides enhanced measurement accuracy and fast logging of current and voltage up to a sample rate of 500000 values per second. The battery simulation option can run profiles stored in ASCII files; these profiles describe the open-circuit voltage and internal resistance versus state of charge. Profiles for common battery types are available in the power supply. The fast logging function can capture narrow spikes and glitches in current and voltage for troubleshooting purposes.

System Integration

Frankfurt-based Allice Messtechnik GmbH is distributor and system integrator for test and measurement equipment. We use high-quality measurement technology from Rohde & Schwarz for system solutions. At Allice Messtechnik you will find technical support as well as service and calibration services for Rohde & Schwarz.

Contact a metrology specialist on Tel +49-69-67724583